POWER4BIO cross-visit to Central Germany – Day 1: Symposium

Bioeconomy in Central Germany region, 23.6.2020

On June 23 and 24, the POWER4BIO cross-visit to Central Germany took place as a virtual event. The sixth cross-visit of a series of ten was organised by the Deutsche Biomasseforschungszentrum (DBFZ), POWER4BIO partner in charge of coordinating the project‘s activities in the Central Germany region, and the support of the Enabling project and the BioEconomy Cluster e.V.

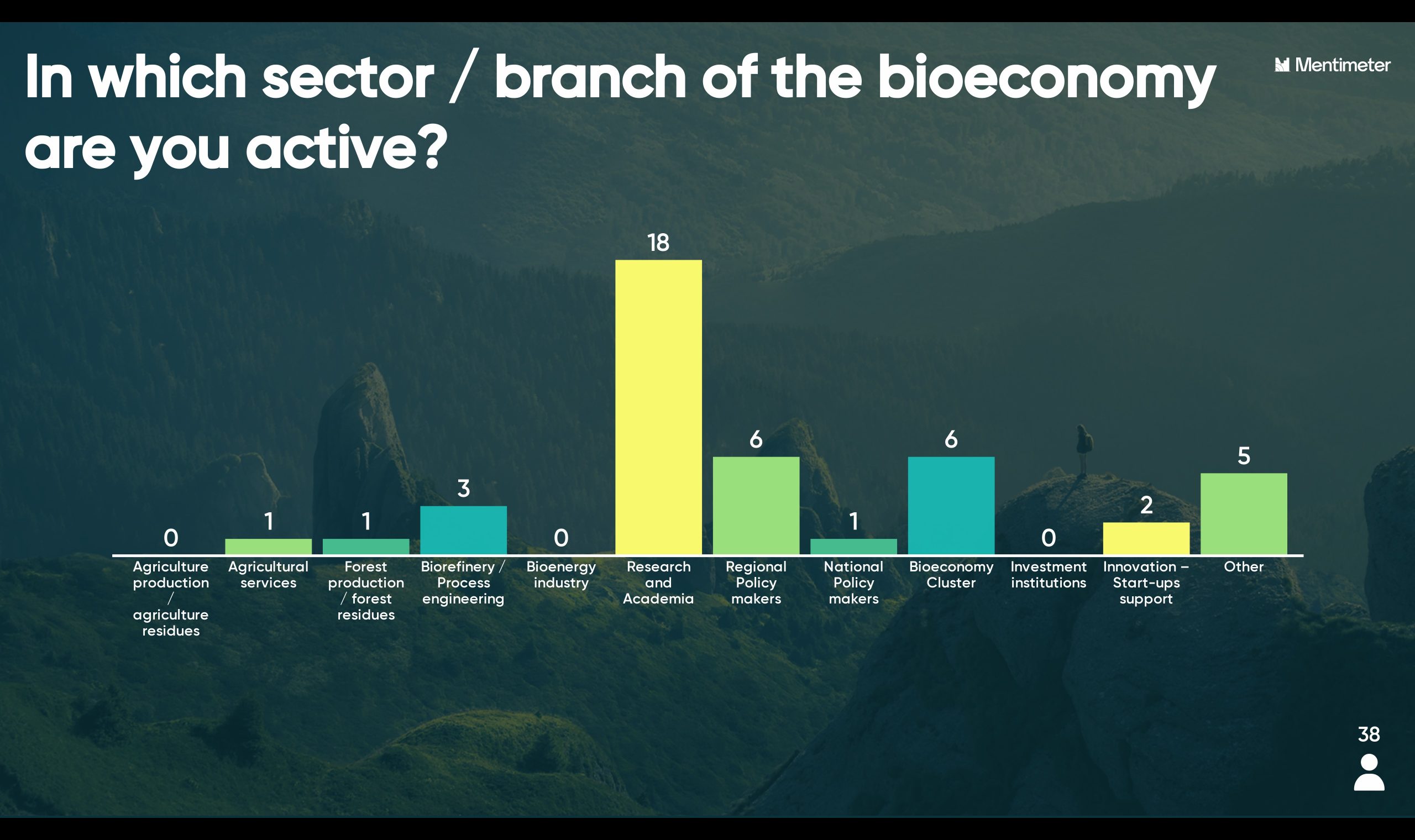

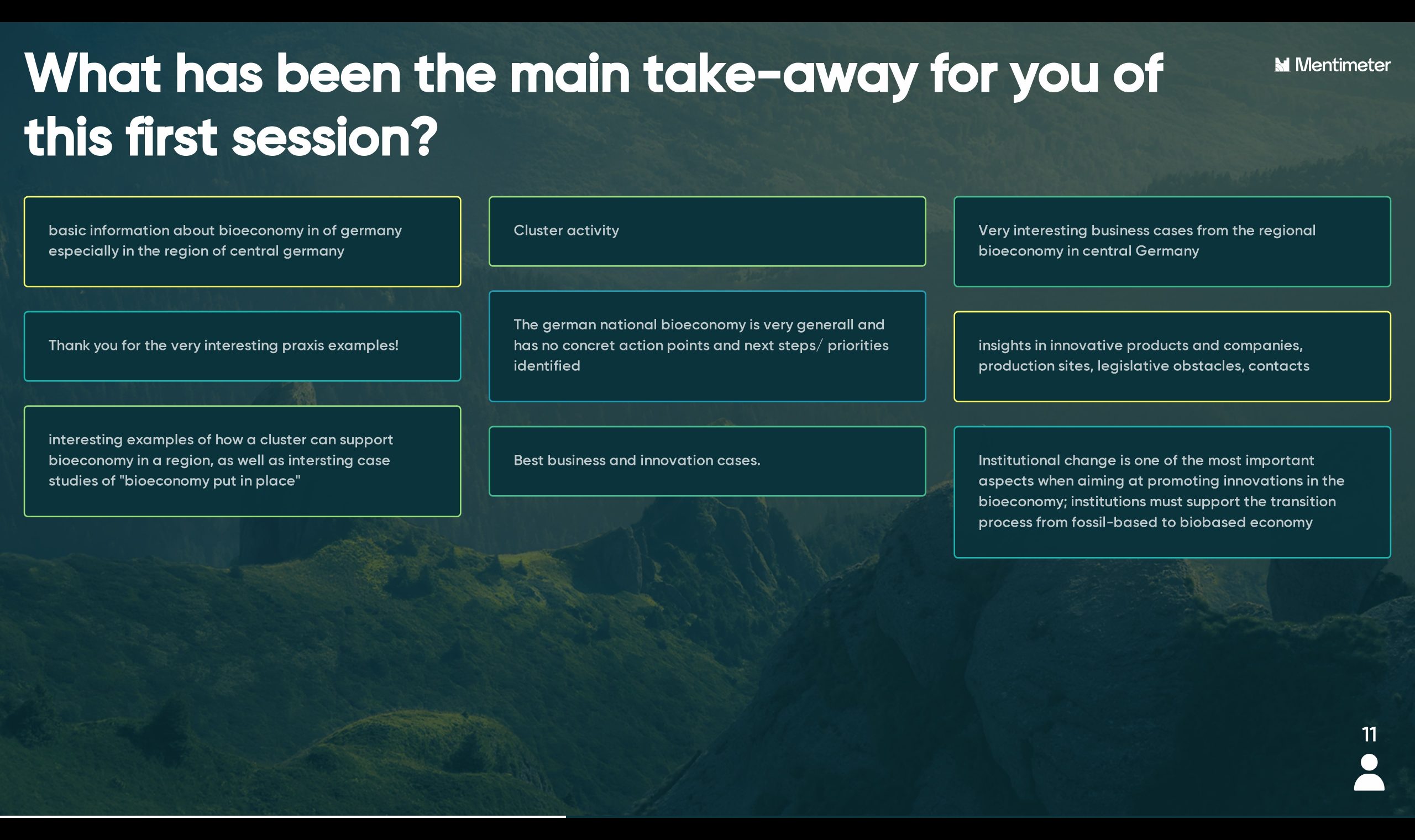

The cross-visit started with a symposium about bioeconomy in Central Germany region on the first day with more than 70 participants. After the welcome note of Dr. Nora Szarka from DBFZ, Dr. Dieter Konold from Project Management Jülich, on behalf of the Federal Ministry of Education and Research (BMBF), gave a keynote speech about the German Bioeconomy Strategy and its political relevance. Afterwards, Prof. Dr. Matthias Zscheile, chairman of the BioEconomy Cluster e.V. board gave an overview of the status quo of bioeconomy in the three federal states Sachsen, Sachsen-Anhalt and Thuringia, that together form the Central Germany region. He also presented some best cases of innovation and industry in the region. Between the presentations, the participants were encouraged to interact and to give feedback using an online polling tool.

In the next session, several best business and innovation cases were presented and provided a view on the main challenges they have faced, as well as the way ahead to overcome them. Amynova Polymers GmbH develops innovative processes for the homogeneous modification of starches and flours. Bernhard Sack, the managing director of Amynova, illustrated the innovative properties of these biopolymers that can for example be used as barrier-forming coatings in packaging papers or as biological adhesives to increase the efficiency of crop protection products in agricultural applications. Currently the products from Amynova Polymers are approved for organic farming.

Jonas Finck, founder of Madebymade GmbH, presented his SME that is based in Leipzig. Madebymade has achieved a high-quality, industrially produced insect protein that serves as a substitute for fish meal and soya from the larvae of the “black soldier fly”. The larvae of this fly offers excellent conditions for obtaining the protein converting almost all organic residues into high-quality proteins and fats. These high-quality, sustainably obtained substances can be produced cost-effectively on an industrial scale and can thus be used worldwide as a recycling source of residual materials and as a source of animal protein.

Fibre-reinforced shaped wood profiles and shells are the products of the presentation of Prof. Dr. Ing. Peer Haller, Chair of timber engineering and construction design of the Technical University Dresden. By compressing the wood cell structure, the boards become very elastic and load bearing and do not break as easily as conventionally worked wood. In addition, they can be reinforced with synthetic fibres afterwards, making them even more stable and weatherproof. This allows plenty of new areas of application in construction and architecture, in lightweight construction and plant engineering as well as in transport and design.

QMILK is a pioneer in sustainable production of fibres and cosmetics based only on renewable raw materials and non-consumable milk proteins. Dr. Anke Domaske, founder of Qmilkfiber, presented her company that strives for sustainable production, without any chemical additives and low use of water and energy. The milk used as raw material is collected from old, sour milk or un-used by-products that would be completely discarded in any other case. The fibre has a natural antibacterial effect and high hydrophilicity, thermo-bonding properties and can be composted.

Following, Romy Brödner and Martin Graffenberger from DBFZ presented the project MoreBio – model region of the bioeconomy, where structural changes in coal regions are analysed and prepared to tap the potential of new value creation for the development of strong bioeconomy regions. Their presentation was followed by introduction of Ecospray as a best case example of circular bioeconomy. Dr. Murree Groom, technical director of Ecospray, gave an introduction to research and development of registration of bio-based plant protection products, presenting a best case example of a garlic-based nematicide to fight plant parasitic nematodes.

Finally, Dr. Alberto Bezama from the Helmholtz Center for Environmental Research (UFZ) presented the development of analysis model SUMINISTRO. Dr. Bezama and his colleagues have assessed a series of bioeconomy networks from an integrated life cycle perspective for the region of Central Germany, which provides as result a series of indicators to identify social, economic and environmental aspects of sustainability in specific regional value chains.

The symposium ended with a panel discussion about the challenges of bioeconomy acceleration at regional level, moderated by Dr. Alberto Bezama from the UFZ. The three panellists were Prof. Dr. Hermann Lotze-Campen from the Potsdam Institute for Climate Impact Research (PIK), Prof. Dr. Matthias Zscheile from the BioEconomy Cluster, and Mr. Flavio Conti, policy officer at the European Network for Rural Development (ENRD).

The panel discussion encompassed the challenges arising from the acceleration of bioeconomy at the regional level. As Prof. Dr. Lotze-Campen highlighted, the special context of each region makes it difficult to generalise the challenges. Yet, in main traits, they are mostly related to the estimation the regional biomass capacity as well as to knowledge and skills for its valorisation.

Additionally, from the experience of the Bioeconomy Cluster, bioeconomy is still a distant concept to local businesses due to many uncertainties in this field. Bio-based products can only compete with their fossil alternatives with the policy support, which makes business dependent on legislation. Furthermore, as the aim of bioeconomy is not to create a niche market but rather a substitution to fossil economy, questions regarding the resource intensification arise: how can we meet producers’ needs and the demand in bioeconomy? Are there enough resources to scale up the production? Is bioeconomy compatible with current consumption patterns?

The cooperation among variety of actors to find answers is hindered by the different timeframes of parties involved. While the research requires several years for a project, the industry instead needs to scale up the production in much shorter time in order to remain on the market. As a conclusion remarks, the panellists agreed that the bioeconomy is a process without quick results but that requires dedication and constance.